Date: 2025.10.31 Click: 78

In automobile transmission systems, clutch pressure plate is a key part of connecting engine and transmission, which is responsible for transferring torque and controlling on/off power. Its performance directly affects the smoothness, fuel economy and reliability of the gearshift. With the development of materials science, heat treatment technology and intelligent control technology, pressure plates design and manufacture is undergoing a leap from mechanical optimization to intelligent development.

I. Pressure Plate Structure Analysis: A Symphony of Precision Design A Symphony of Precision Design

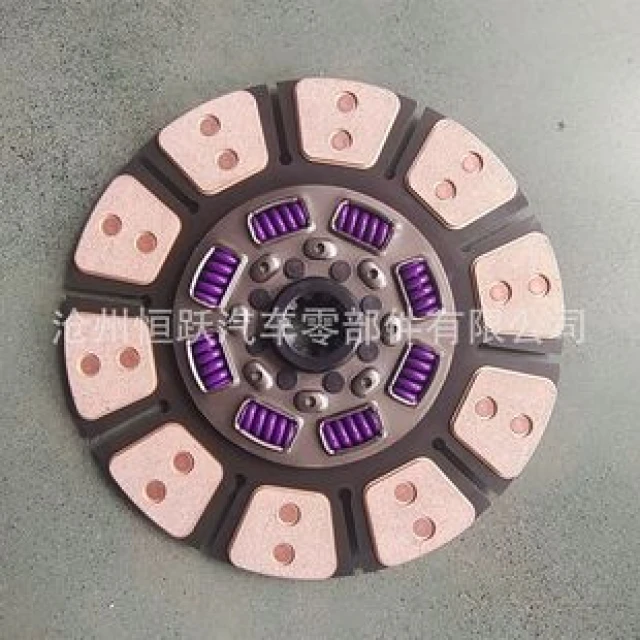

The structure design of pressure plate is a perfect combination of mechanics and materials science. Its core components include friction plates, pressure plate valve body, diaphragm spring (or coil springs) and transmission plates. These components work together to deliver power transmission:

Friction Plates: Made of high carbon or alloy steel coated with molybdenum or ceramics, it maintains a stable friction coefficient even at high temperatures, while also possessing abrasion resistance and heat fade resistance.

Spring assembly: Because of its nonlinear elasticity, diaphragm springs can provide both clamping and detachment forces, reduce the number of parts and reduce the weight of the system; coil springs optimize pressure distribution through multi-stage stiffness design.

Transmission plate: As a bridge connecting pressure plate and the flywheel, riveting process and material strength directly affect torque transmission efficiency, and a balance between flexibility and fatigue resistance is required.

Design challenge: In a lightweight trend, pressure plate need to balance weight loss (for example, using magnesium alloys) with structural strength. One OEM, using topology optimization technology, reduced pressure plate weight by 15% while increasing stiffness by 8%, significantly improving the performance of NVH (noise, vibration and rigor) transmission system.

II. Performance Optimization: The durability of a double breakthrough pressure plate in heat treatment and materials science depends on the synergy of material selection and heat treatment processes:

Material Innovation: Alloy steel (e.g., 42CrMo4) can achieve surface hardness of 58-62 HRC through carburizing and quenching, while maintaining core toughness and increasing impact resistance by 30%.

Composite applications: Ceramic-coated friction plates are widely used in heavy trucks, and their high temperature resistance (up to 800°C) extends the life of pressure plate to more than twice that of conventional materials.

Heat treatment process: Vacuum quenching technology reduces oxidation and decarbonization, resulting in more uniform surface mass; Cryogenic treatment (-196°C) eliminates residual stress, reduces deformation and improves dimensional stability.

Test criteria: pressure plate must pass 1 million durability testing required by SAE J2407 to simulate thermo-mechanical coupling damage in extreme conditions and ensure adequate design margin.

III. Fault Diagnosis: Early warning systems from Abnormal Noise to Slippage Pressure plate faults are usually characterized by abnormal noise, sliding or accelerated wear, usually related to material failure or improper installation:

Abnormal Noise: the wear of friction plates causes metal to contact metal, or spring to break causing an abnormal vibration frequencies. Vibration spectrum analysis can identify the source of the fault; for example, in a vehicle model, loose riveting of the transmission plate caused excessive vibration in the 1200Hz frequency band.

Slide: Insufficient clamping force (e.g., diaphragm spring fatigue) or reduced friction coefficient (such as lubricant contamination) is the main cause. Infrared thermal imaging can quickly identify local overheating areas and guide targeted repair.

Wear: High-temperature oxidation or frequent local contact can accelerate the wear and tear of friction plate. Preventative maintenance recommends checking the thickness of friction plate every 60,000 km and replacing them if they are less than 1.5mm.

IV. INTRODUCTION System Matching: Artistic pressure plate with Torque Transmission balance need to be precisely matched to other components of the clutch assembly,such as the flywheel and release bearing, to achieve dynamic balance of power transmission:

Pressure torque curve: The pressure of the pressure plate needs to be synchronized with the engine torque output of the engine to avoid shift shock. For example, hybrids adjust diaphragm spring pretension to control + ± 5% force fluctuation.

Synchronized Release Stroke: release bearing stroke and pressure plate stroke must correspond strictly, otherwise will occur incomplete detachment or heavy pedal. The automatic gearbox reduced the release lag from 1.2mm to 0.3mm by optimizing the curvature of the gearbox plate.

NVH Optimization: pressure plate stiffness requires avoidance of resonance frequency of transmission system. A sports sedan increased the number of pressure plate ribs and increased the resonance frequency from 800 hertz to 1,200 hertz, effectively suppressing idle vibration.

V. Future trends: a dual revolution of intelligence and weight

Along with the automobile industry's transition to electric and intelligent, pressure plate technology is undergoing two major transformations:

Materials lightweight: Magnesium alloy pressure plates are 40% lighter than steel products and have been tested in small batch models. 3D printing enables integrated molding of complex structures, reducing assembly errors and increasing design freedom.

Intelligent upgrade: Embedded sensors monitor clamping force, temperature and wear in real time. Data is transmitted to the TCU via the CAN bus for adaptive clutch control; the wired clutch system eliminates mechanical connections, and pressure plate pressure is precisely controlled by the motor, reducing shift response time to less than 100ms.

Industry impact: New energy vehicles require higher resistance to heat from pressure plates (which respond quickly to motor torque transients), while smart driving technology requires deep integration of pressure plate with vehicle control system, providing a data base for fault prediction and health management. In conclusion, the evolution of clutch pressure plates technology, from precision mechanical manufacturing to intelligent electronic control integration, reflects the transformation trajectory of the automotive industry. In the future, as materials science, sensor technology and artificial intelligence deepen their convergence, pressure plates will no longer simply be passive drivers, but the core nodes of intelligent transmission system, laying the foundation for a more efficient and reliable driving experience.

Please leave your requirements and contact information, and we will send you the quotation information as soon as possible.