Date: 2025.10.16 Click: 58

You rely on an oil cooler to manage heat and protect your engine. This device ensures your engine oil stays within the optimal 195°F to 220°F range. Proper temperature control helps maintain lubrication, prevents overheating, and supports peak engine performance every time you drive.

Key Takeaways

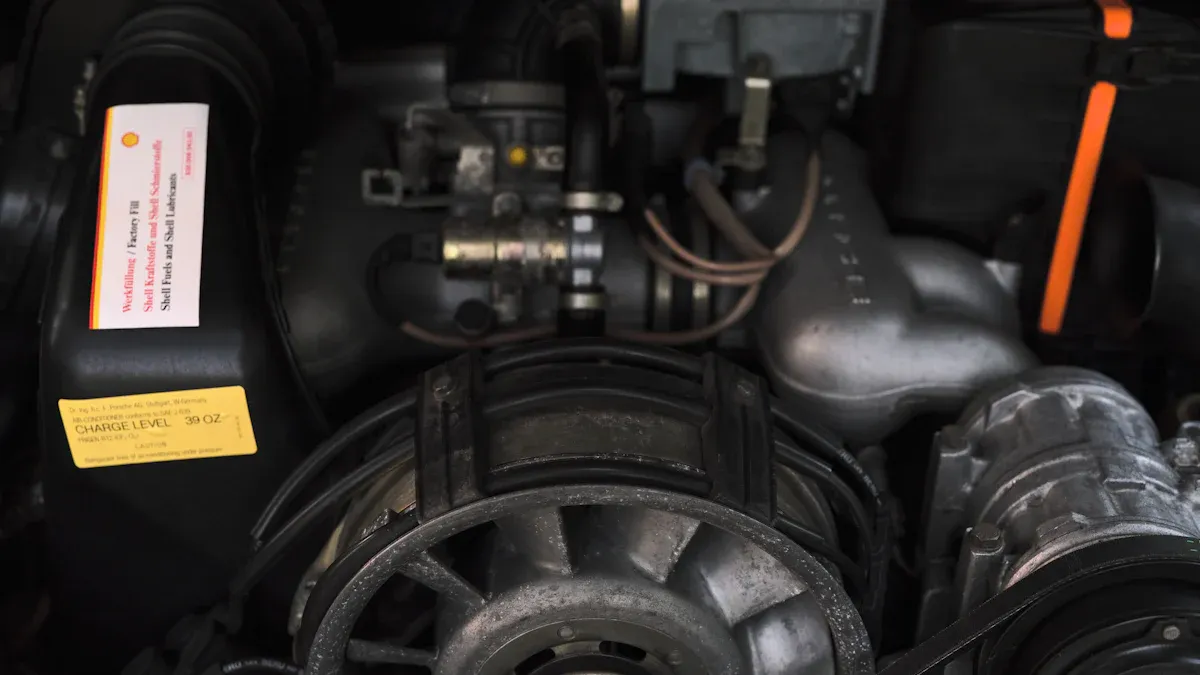

You depend on an oil cooler to keep your engine running smoothly, especially under stress. This device acts as a heat exchanger, much like a radiator, but it targets your engine’s lubricating oil. When hot oil leaves the engine, it enters the oil cooler, where heat transfers away before the oil returns to protect vital components.

At its core, the oil cooler functions as a heat exchanger. Hot oil leaves the engine and enters the cooler, where heat is removed before the oil returns to lubricate critical components.

By cooling the engine oil, you enhance lubrication efficiency and prevent overheating of essential engine parts. This process becomes even more important when you drive in demanding conditions, such as towing, racing, or navigating steep terrain.

Maintaining the right oil temperature is crucial for your engine’s health. An oil cooler transfers excess heat from the oil to a cooler medium, such as air or engine coolant. This keeps the oil within the ideal range, which is vital for effective lubrication and overall engine performance.

When you install an oil cooler, you can expect a reduction in engine oil temperature by 20 to 30°F, especially in high-performance vehicles. This drop in temperature helps prevent premature engine wear and supports consistent performance.

| Benefit | Description |

|---|---|

| Extended Engine Life | Proper lubrication reduces wear and tear, extending the engine’s lifespan. |

| Improved Performance | The engine runs more efficiently when the oil is at the right temperature. |

| Fuel Efficiency | Optimal oil temperature can improve fuel economy, saving you money in the long run. |

You also help the environment by keeping your engine oil at the right temperature. Efficient oil cooling leads to better fuel economy and lower emissions, which benefits both your wallet and the planet.

You can choose from several types of oil coolers, each designed for specific needs and vehicle types. The two most common are air-cooled and liquid-cooled oil coolers.

| Type of Cooler | Mechanism Description |

|---|---|

| Liquid-Cooled | Routes hot oil through small tubes inside a unit filled with coolant, allowing heat transfer to the coolant. |

| Air-Cooled | Relies on ambient air flowing over finned tubes to dissipate heat from the oil. |

| Feature | Air-Cooled | Liquid-Cooled |

|---|---|---|

| Cooling Method | Uses natural air to dissipate heat | Circulates coolant through internal channels |

| Efficiency | Less efficient for high-performance engines | More efficient, maintains ideal operating temperature |

| Application | Suitable for small capacity engines and some large engines in colder climates | Ideal for large capacity engines that rev high |

| Noise Level | Noisy due to lack of insulation | Quieter due to additional insulation |

| Environmental Impact | More polluting and less eco-friendly | More environment-friendly |

You will also find specialized designs, such as stacked plate coolers and oil-to-water coolers, which offer unique benefits:

| Type of Oil Cooler | Efficiency and Features |

|---|---|

| Stacked Plate Coolers | Up to 30% more efficient than other designs; low flow restriction; vacuum brazed for reliability; features turbulators for better heat dispersion. |

| Oil-to-Water Coolers | Uses engine water for cooling; protects from environmental damage; can be installed in less vulnerable locations. |

Mounting options vary based on your vehicle and needs:

| Mounting Option | Description |

|---|---|

| Static, ram-air cooler | Best placed in a location with maximum airflow; however, it can be blocked by other front-mounted components. |

| Sandwich adapter | A spacer plate is placed between the filter landing and the factory filter, moving the filter closer to the ground. |

| Spin-on adapter | Uses a filter relocation kit to move the filter mount to a more advantageous position on the vehicle. |

The oil-cooling system includes several key components. Fittings and hoses connect the cooler to the engine, ensuring a continuous flow of oil. Proper installation and secure attachment of these parts prevent leaks and vibration damage, which are essential for long-term engine reliability.

When you integrate an oil cooler with your engine’s coolant system, you maintain optimal oil temperatures and prevent overheating. This integration ensures a steady flow of cooled oil back to the engine, which is especially important for turbocharged or heavy-duty engines that generate more heat.

By understanding how an oil cooler functions, you can make informed decisions about protecting your engine and maximizing its performance.

Oil Cooler Benefits

You benefit most from an oil cooler if you drive a high-performance car, tow heavy loads, or operate commercial vehicles. These vehicles generate more heat, especially under stress. Factory tow packages often include oil coolers because they help maintain engine performance during demanding tasks. Monitoring oil and transmission temperatures becomes crucial when you tow in mountainous areas or haul heavy equipment. In commercial and industrial vehicles, oil coolers keep lubricating oil at safe temperatures, preventing overheating and reducing engine wear. Upgrading the cooling system in a performance vehicle can also increase its resale value, as buyers appreciate advanced thermal management.

Regular maintenance keeps your oil cooler working efficiently and extends your engine’s life. Follow these steps:

| Benefit | Explanation |

|---|---|

| Reduces repair costs | Regular maintenance prevents engine damage and lowers long-term expenses. |

| Enhances performance | Proper cooling reduces wear and supports engine longevity. |

| Cost-effective | Savings on repairs and maintenance add up over time. |

Watch for these common signs of oil cooler trouble:

You may also notice oil in the coolant, excessive coolant loss, or reduced engine performance. Ignoring these symptoms can lead to severe engine damage or even complete failure. Clogging from debris, damaged seals, or loose connections often cause these issues. Regular inspection and prompt repairs help you avoid costly breakdowns and keep your engine running smoothly.

You protect your engine from overheating and wear by understanding the value of an oil cooler. Regular inspections and cleaning help you avoid costly repairs and extend engine life.

| Benefit | Description |

|---|---|

| Enhanced Performance | Maintains optimal engine power |

| Cost Savings | Reduces long-term maintenance |

You should inspect your oil cooler every 6 months or 5,000 miles. Regular checks help you spot leaks, corrosion, or debris early.

You can install an oil cooler if you have mechanical experience. Most kits include instructions. Seek professional help if you feel unsure.

Watch for these symptoms to prevent engine damage.

Please leave your requirements and contact information, and we will send you the quotation information as soon as possible.